Heating systems

In recent years, the development of logistics systems has led to an increased demand for heaters for freeze and condensation prevention.

And simultaneously, the needs for heaters have become more diverse.

To meet these needs, we engage in the design, manufacturing, sales, and installation of heaters for freeze and condensation prevention, focusing on advanced technology and extensive experience. Our expertise covers areas

such as heaters for refrigerated warehouse floors, heat-resistant doors, and pipelines.

A variety of requests

for responce.

We have a lineup of industry-leading products that boast high performance, efficiency, and safety, including

the self-regulating heater [Selcon Heater], [Surlyn Heat], [heaters for simplified toilet piping], [heaters for

drainage (roof drains)]and more.

Through these products, we cater to a wide range of requests, including preventing freezing in pipelines in

cold regions, preventing floor freezing in refrigerated warehouses, providing floor heaters for ultra-low

temperature freezing rooms for tuna storage (-60°C), preventing condensation around refrigerators and

freezers, preventing frost formation beneath refrigerated warehouse floors, and addressing heat bridge issues against incoming cold air. We are committed to meeting various demands from our customers.

-

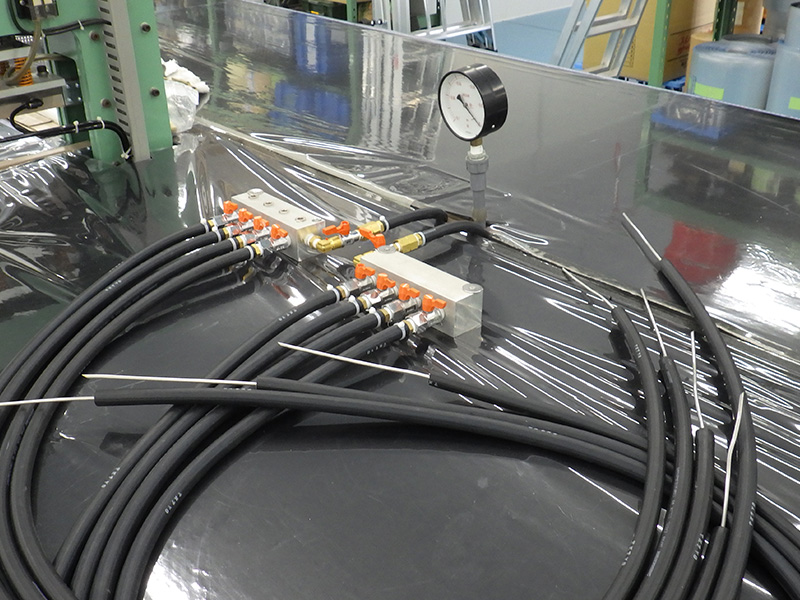

Selcon Heater

(Self-regulating heaters) -

Surlyn Heat

(Flat shape heating element/Carbon heaters) -

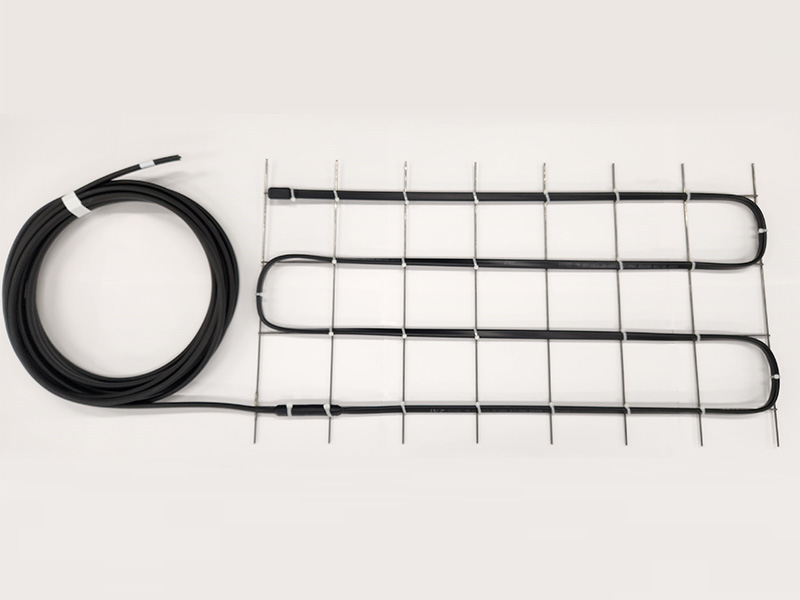

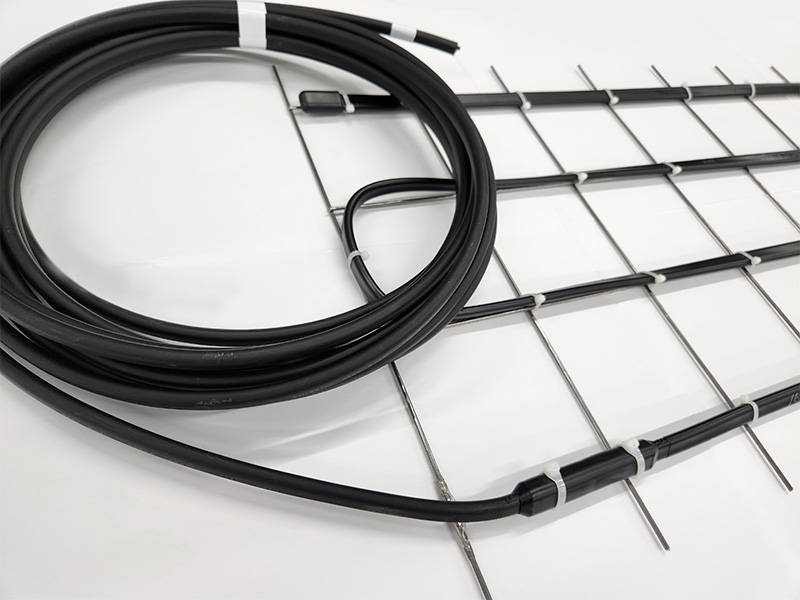

Mesh type

(The product incorporating Selcon Heater into a wire mesh unit.) -

(with temperature controller)

*Separate embedding of the floor temperature sensor is required.

(On/Off switch only)

Facility information

-

-

Machine tools

Injection molding machine 5 units Drilling machine 3 units -

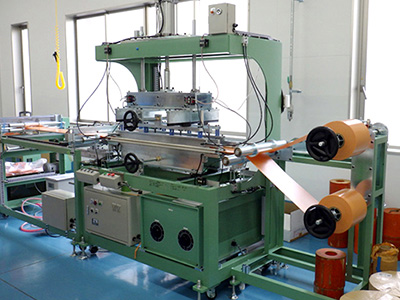

Specialized machine

Sealing machine for Surlyn Heat 6 units Automatic wire stripper 5 units Sealing machine for heating element outer covering sheet 1 unit -

Inspection/

measuring equipmentVolt-ampere meter aa 4 units Insulation/withstanding hitester 1 unit Insulation resistance tester 12 units Circuit meter (tester) 6 units Overhead line current meter (clamp meter) 4 units Thermometer 4 units Calipers 1 unit Micrometer 1 unit

-

Production factory

-

Kashiwa Factory (Head Office / Accounting Department)

Main handled products

Various Industrial Heaters

Rainwater storage and permeation tank

-

1-28-1 Aobadai, Kashiwa City, Chiba 277-0055, Japan

(〒277-0055千葉県柏市青葉台1-28-1)

- (04)7186-7711

- (04)7186-7718

- TOP

- Heating systems